As an indispensable and important equipment in the power and electrical industries, the copper busbar bending machine has a direct impact on the production efficiency and product quality of the enterprise due to its stable performance and convenient operation. This article will introduce the copper busbar bending machine in detail, including its structural principle, usage characteristics, application fields, and maintenance, in order to provide readers with a comprehensive and in-depth understanding.

1. Structural principle of copper busbar bending machine

The copper busbar bending machine is mainly composed of the fuselage, hydraulic system, electrical control system, mold and other parts. The fuselage is welded with high-strength steel and has sufficient rigidity and stability; the hydraulic system realizes the bending of the copper busbar by controlling the extension and contraction of the oil cylinder, and has the characteristics of high pressure, high speed and high precision; the electrical control system is responsible for the start, stop, speed regulation and other functions of the entire equipment to ensure the normal operation of the equipment.

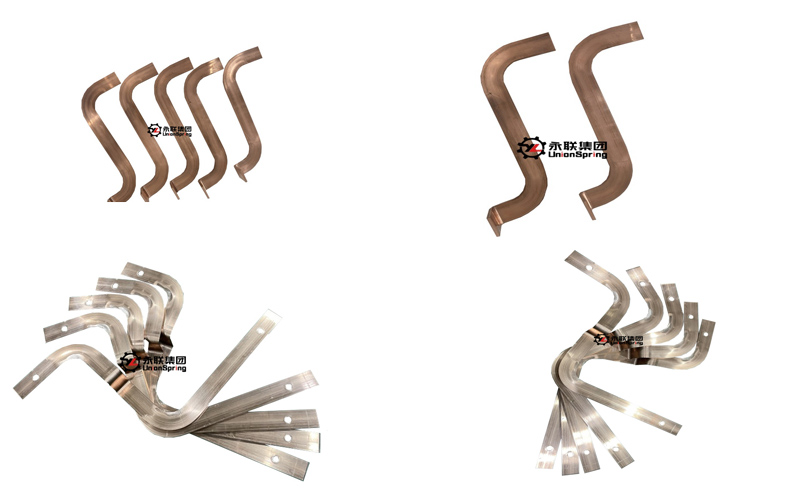

During the bending process, the copper busbar is placed between the molds, and pressure is applied through the hydraulic system to make the copper busbar undergo plastic deformation under the guidance of the mold, thereby achieving the expected bending effect. At the same time, the electrical control system accurately controls parameters such as pressure and speed to ensure the stability and accuracy of the bending process.

2. Features of copper busbar bending machine

1. High efficiency: The copper busbar bending machine adopts advanced hydraulic system and electrical control system, which can quickly and accurately complete the bending work of copper busbar and improve production efficiency.

2. High precision: The equipment has a high-precision control system, which can ensure the accuracy of parameters such as bending angle and radius, and meet various high-precision processing requirements.

3. Easy operation: The equipment adopts humanized design, and the operation interface is simple and easy to understand, which reduces the difficulty of operation and improves work efficiency.

4. Good stability: The equipment is made of high-strength steel, with a stable structure, can withstand a large workload, and ensure the long-term stable operation of the equipment.

5. Wide range of applications: The copper busbar bending machine is suitable for copper busbar bending processing of various specifications and materials, and is widely used in power, electricity, new energy and other fields.

3. Application fields of copper busbar bending machine

1. Power industry: In the power system, copper busbar is an important conductive material and is widely used in substations, power plants and other places. The copper busbar bending machine can meet the high-precision and high-efficiency requirements of the power industry for copper busbar bending processing, and ensure the safe and stable operation of the power system.

2. Electrical industry: In the electrical manufacturing process, copper busbars are widely used in various electrical equipment as electrical connectors. The copper busbar bending machine can accurately bend the copper busbar according to the needs of different electrical equipment to ensure the performance and reliability of electrical equipment.

3. New energy industry: With the rapid development of the new energy industry, copper busbars are increasingly used in new energy fields such as solar energy and wind energy. The copper busbar bending machine can meet the special needs of the new energy industry for copper busbar bending processing, and provide strong support for the development of the new energy industry.

4. Maintenance of copper busbar bending machine

1. Regular inspection: Regularly check the hydraulic system, electrical control system and other parts of the copper busbar bending machine to ensure the normal operation of each component.

2. Cleaning and maintenance: Keep the equipment clean, and regularly clean up oil, dust and other debris on the surface of the equipment to prevent the equipment from rusting and corrosion.

3. Lubrication and maintenance: Regularly lubricate the lubrication parts of the equipment to ensure the smooth operation of the equipment.

4. Mold maintenance: Regularly check the wear of the mold, replace the severely worn mold in time, and ensure the accuracy and stability of the bending process.

5. Safety protection: When using the equipment, strictly abide by the safety operating procedures to ensure the safety of personnel and equipment.

In short, as an indispensable and important equipment in the power and electrical industries, the stability of the performance and the convenience of operation of the copper busbar bending machine are of great significance to the production efficiency and product quality of the enterprise. Through the introduction of the structural principle, usage characteristics, application fields and maintenance of the copper busbar bending machine, I believe that readers have a comprehensive and in-depth understanding of the copper busbar bending machine. In the future use process, we should give full play to the advantages of the copper busbar bending machine to provide strong support for the development of the enterprise.