With the rapid development of renewable energy technology, the stability and efficiency of energy storage systems as an important part of smart grids have received widespread attention. As a key device in the energy storage system, the performance of the energy storage inverter directly affects the operation effect of the entire system. As the core equipment for producing inverter inductors, the technical level and manufacturing precision of the energy storage inverter inductor winding machine are directly related to the performance and reliability of the inverter.

1. The importance of energy storage inverter inductor winding machine

Energy storage inverter inductor winding machine is a special equipment for producing inverter inductors. Inductors are important components in inverters, and their performance directly affects the output waveform, efficiency, and electromagnetic compatibility of the inverter. Therefore, the technical level and manufacturing precision of the inductor winding machine are crucial to the overall performance of the inverter.

First, the high-precision winding technology of the energy storage inverter inductor winding machine can ensure the precise and stable electrical parameters of the inductor, thereby improving the output waveform quality of the inverter. Secondly, the higher the degree of automation and intelligence of the winding machine, the higher the production efficiency, while reducing production costs and improving market competitiveness. In addition, the stability and reliability of the winding machine are also key factors to ensure the long-term stable operation of the inverter.

2. Technical features of energy storage inverter inductor winding machine

1. High-precision winding technology

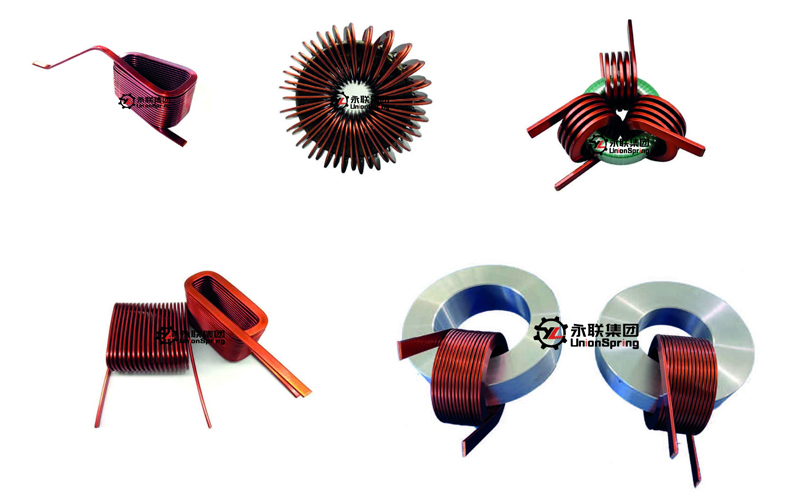

The energy storage inverter inductor winding machine adopts high-precision winding technology, which can ensure the accurate and stable parameters of the inductor coil, such as the number of turns, wire diameter, and arrangement method. This high-precision winding technology can greatly improve the electrical performance of the inductor and make the inverter output waveform smoother and more stable.

2. High degree of automation and intelligence

Modern energy storage inverter inductor winding machines generally adopt automation and intelligent technology, which can realize automatic loading and unloading, automatic winding, automatic welding and other functions. This highly automated production method can greatly improve production efficiency and reduce production costs. At the same time, the application of intelligent technology can also realize real-time monitoring and fault diagnosis of the production process, ensuring the stability and reliability of the production process.

3. High stability and reliability

Energy storage inverter inductor winding machines are usually made of high-quality materials and precise processing technology, with high stability and reliability. In addition, the winding machine is also equipped with perfect protection measures and fault diagnosis systems, which can timely alarm and take corresponding measures when a fault occurs to ensure the continuity and stability of the production process.

3. Development trend of energy storage inverter inductor winding machine

With the continuous development of renewable energy technology and the in-depth promotion of smart grid construction, energy storage inverter inductor winding machines will face a broader development space and more severe market competition. In the future, the development trend of energy storage inverter inductor winding machines will be mainly reflected in the following aspects:

1. High precision and high efficiency

In the future, energy storage inverter inductor winding machines will pay more attention to improving winding accuracy and production efficiency. By adopting more advanced winding technology and automation equipment, higher winding accuracy and faster production efficiency can be achieved, thereby meeting the market demand for high-performance inverters.

2. Intelligent and digital upgrades

Intelligence and digitalization are important development trends in the future manufacturing industry. Energy storage inverter inductor winding machines will further strengthen the application of intelligent and digital technologies, realize real-time monitoring and remote control of the production process, and improve the transparency and controllability of the production process.

3. Green environmental protection, energy saving and consumption reduction

With the continuous improvement of environmental awareness and the increasing tension of energy resources, green environmental protection and energy saving and consumption reduction will become an important development direction of energy storage inverter inductor winding machines. By adopting environmentally friendly materials and energy-saving technologies, energy consumption and emissions in the production process can be reduced to achieve green production.

IV. Conclusion

As the core equipment for producing inverter inductors, the technical level and manufacturing precision of energy storage inverter inductor winding machines are crucial to the performance and reliability of inverters. In the future, with the continuous development of renewable energy technology and the in-depth promotion of smart grid construction, energy storage inverter inductor winding machines will face broader development space and more severe market competition. We need to continuously strengthen technological innovation and industrial upgrading, improve the technical level and manufacturing precision of winding machines, and make greater contributions to the development of renewable energy and smart grids.