In modern industrial production, the application of precision machinery is becoming more and more extensive, especially in the fields of metal processing and automobile parts manufacturing. High-precision and high-efficiency mechanical equipment has become a key factor in promoting the development of the industry. Camless spring machine, as a rising star in this field, is gradually changing the pattern of the traditional spring manufacturing industry with its unique design concept and excellent performance.

1. Technical background of camless spring machine

In the traditional spring manufacturing process, the cam mechanism is an indispensable component. However, the design, manufacturing and debugging of the cam mechanism are relatively complex, and there are problems such as fast wear, high maintenance cost and difficult adjustment. In order to solve these problems, the camless spring machine came into being. It adopts advanced electronic control system and precise transmission mechanism to realize precise control of the spring manufacturing process, greatly improving production efficiency and product quality.

2. Working principle of camless spring machine

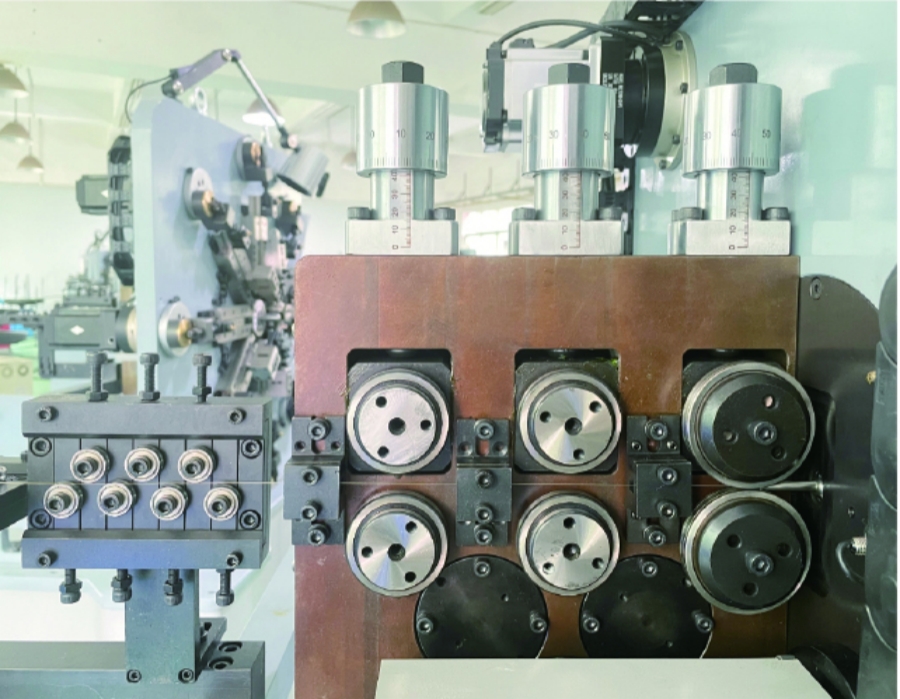

The working principle of camless spring machine is mainly based on the coordinated work of electronic control system and servo motor. During the spring manufacturing process, the electronic control system adjusts the speed and position of the servo motor in real time according to the preset parameters and process requirements, thereby realizing precise control of the spring forming process. This control method not only improves the precision and consistency of the spring, but also greatly reduces the scrap rate in the production process.

III. Advantages of camless spring machine

1. High precision: The camless spring machine adopts advanced electronic control system and servo motor to achieve precise control of the spring forming process, thereby ensuring the high precision and consistency of the spring.

2. High efficiency: Since the camless spring machine adopts an electronic control system, it can achieve fast and accurate parameter adjustment and process switching, thereby greatly improving production efficiency.

3. Low maintenance cost: The camless spring machine adopts a camless design, which reduces the wear and maintenance cost of the traditional cam mechanism. At the same time, the stability and reliability of the electronic control system are also higher, further reducing the maintenance cost.

4. Flexibility: The camless spring machine can adapt to the manufacturing needs of springs of different specifications and materials, and has strong flexibility and adaptability.

5. Environmental protection and energy saving: The camless spring machine adopts advanced energy-saving technology and environmentally friendly materials in the manufacturing process, realizing green and environmentally friendly production with low energy consumption and low emissions.

IV. Application field of camless spring machine

The camless spring machine has broad application prospects in metal processing, automotive parts manufacturing, aerospace and other fields. For example, in the manufacturing of automotive parts, camless spring machines can manufacture high-precision, high-quality spring products to meet the high requirements of automotive suspension systems, brake systems, transmission systems, etc. for spring performance. In the field of aerospace, camless spring machines can manufacture spring products with special properties such as high temperature resistance, corrosion resistance, and high strength to meet the strict requirements of aerospace vehicles for springs.

V. Development trend of camless spring machines

With the continuous advancement of science and technology and the continuous development of industrial production, camless spring machines will present a broader development prospect in the following aspects:

1. Intelligence: With the continuous development of technologies such as artificial intelligence and the Internet of Things, camless spring machines will achieve more intelligent production and management. Through interconnection with other intelligent devices, real-time collection and analysis of production data can be realized, further improving production efficiency and product quality.

2. Flexibility: With the continuous changes in market demand and the increase in personalized needs, camless spring machines will pay more attention to flexible production. Through modular design, rapid mold change and other technical means, the ability to quickly respond to market demand and meet customer personalized needs can be achieved.

3. Environmental protection and energy saving: With the continuous improvement of environmental awareness and the increasingly severe energy crisis, camless spring machines will pay more attention to the research and development and application of environmental protection and energy-saving technologies. By adopting new environmentally friendly materials and optimizing production processes, low-energy consumption and low-emission green environmental protection production can be achieved.

In short, as a new type of spring manufacturing equipment, camless spring machines are gradually changing the pattern of traditional spring manufacturing industry with their advantages of high precision, high efficiency and low maintenance cost. With the continuous advancement of science and technology and the continuous development of industrial production, camless spring machines will present a broader development prospect in terms of intelligence, flexibility, environmental protection and energy saving.