In the field of precision equipment in the manufacturing industry, the enameled copper flat wire winding machine is undoubtedly a shining pearl. With its high efficiency, precision and stability, it plays an irreplaceable role in the production process of electronic components such as motors, transformers, and inductors. This article will deeply explore the technical principles, structural characteristics, application advantages and future development trends of the enameled copper flat wire winding machine, and lead readers into this world of precision manufacturing.

1. Technical principles and core components

The enameled copper flat wire winding machine, as the name suggests, is an automated equipment specially used to wind enameled copper flat wire (a copper flat wire coated with insulating paint on the surface) according to predetermined parameters. Its technical principle is based on a precise servo control system and advanced CNC programming technology. By accurately calculating and controlling the tension, speed, position and other parameters of the wire, efficient and precise winding operations are achieved.

In terms of core structure, the enameled copper flat wire winding machine is mainly composed of the following parts:

1. Control system: As the "brain" of the entire equipment, the control system is responsible for receiving the winding parameters input by the user, such as the number of coil layers, number of turns, spacing, etc., and converting them into machine executable instructions to drive the various execution components to work together.

2. Servo drive system: including servo motors, drivers and transmission mechanisms, responsible for accurately controlling the speed, direction and position during the winding process to ensure the accuracy and stability of the winding.

3. Tension adjustment device: used to adjust the tension of the enameled copper flat wire during the winding process to avoid coil deformation or wire breakage caused by over-tightening or over-loosening, and ensure product quality.

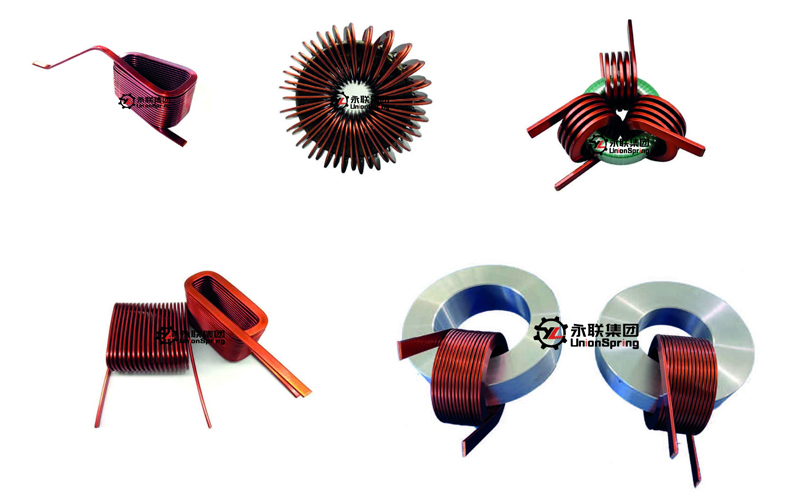

4. Winding mechanism: It is the core component for performing winding actions, usually composed of winding heads, guide rails, clamps, etc., which can be flexibly adjusted to meet the needs of coils of different specifications and shapes.

5. Safety protection system: including emergency stop buttons, photoelectric sensors, etc., to ensure that the power supply can be quickly cut off in the event of an abnormality to protect the safety of operators and equipment.

2. Application advantages and market prospects

The application advantages of enameled copper flat wire winding machines in the production of electronic components are significant, mainly reflected in the following aspects:

1. Improve production efficiency: The automated winding machine can operate continuously, reduce manual intervention, significantly improve production efficiency, and reduce production costs.

2. Improve product quality: By precisely controlling the winding parameters, the consistency and stability of the coil are ensured, and the electrical performance and reliability of the product are improved.

3. Strong adaptability: It can be flexibly adjusted according to the winding requirements of different products to meet the production requirements of coils of different specifications and shapes.

4. Reduce labor intensity: Automated operation reduces the labor intensity of workers, improves the working environment, and improves production safety.

With the rapid development of the electronics industry, the demand for electronic components continues to increase. As one of the key production equipment, the enameled copper flat wire winding machine has a very broad market prospect. Especially in emerging fields such as new energy vehicles, smart grids, and industrial automation, the demand for high-quality and high-efficiency electronic components is more urgent, which provides a broad development space for enameled copper flat wire winding machines.

3. Technological innovation and future trends

Faced with increasingly fierce market competition and changing market demands, technological innovation of enameled copper flat wire winding machines is particularly important. In the future, the technological development in this field will show the following trends:

1. Intelligent upgrade: Introduce advanced technologies such as artificial intelligence and big data to realize intelligent control and optimization of winding machines, improve production efficiency and product quality.

2. High precision and high speed: With the advancement of motor control technology and material science, winding machines will develop in the direction of higher precision and higher speed to meet the production needs of more sophisticated electronic components.

3. Modular design: The modular design concept enables the winding machine to be quickly configured and upgraded according to different needs, improving the flexibility and adaptability of the equipment.

4. Green manufacturing: Focus on energy conservation, emission reduction and environmental protection requirements, adopt low-energy consumption, low-noise and pollution-free design solutions, and promote the green transformation of the manufacturing industry.

In summary, as one of the important equipment for the production of electronic components, the enameled copper flat wire winding machine has strong vitality and broad development prospects in terms of technical principles, structural characteristics, application advantages and future development trends. With the continuous advancement of technology and the continuous expansion of the market, we have reason to believe that the enameled copper flat wire winding machine will play a more important role in the future manufacturing industry.