In modern precision manufacturing, connector spring machines play a pivotal role. As a highly specialized production equipment, connector spring machines have shown strong application value in many fields such as electronics, communications, and automobiles with their high efficiency, precision, and reliability. This article will elaborate on the working principle, technical characteristics, application fields, and future development trends of connector spring machines.

1. Working principle of connector spring machines

The working principle of connector spring machines is mainly based on precision machining technology and material science. Through the preset CNC program, the machine can accurately control the motion trajectory of processing tools such as cutters and molds, and then cut, bend, and stamp on the raw materials, and finally produce connector springs that meet the requirements. During the entire processing process, the machine can monitor and adjust the processing parameters in real time to ensure the stability and consistency of product quality.

2. Technical characteristics of connector spring machines

1. Efficiency: The connector spring machine adopts advanced automation control technology, which can realize high-speed and continuous processing and greatly improve production efficiency.

2. Accuracy: Through the precise CNC system and servo drive device, the machine can ensure the stability of processing accuracy and meet the manufacturing needs of high-precision connectors.

3. Reliability: The machine adopts high-quality materials and advanced manufacturing technology, has high reliability and durability, and can operate stably for a long time.

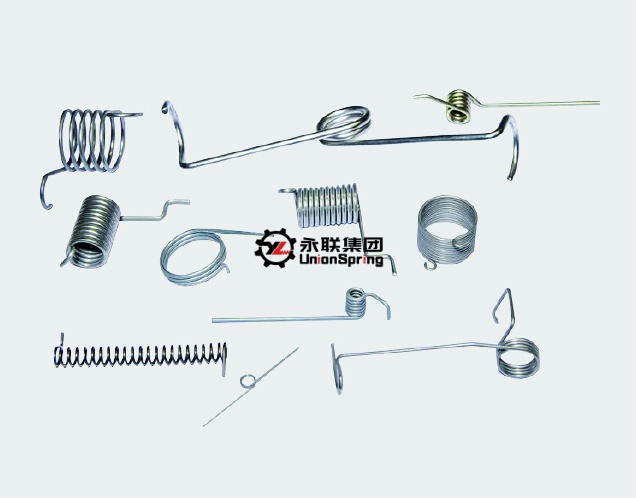

4. Flexibility: The connector spring machine supports a variety of processing modes and parameter settings, and can adapt to the manufacturing needs of connector springs of different specifications and materials.

III. Application fields of connector spring machines

1. Electronic industry: In electronic products, connector springs are widely used in the connection of circuit boards and power cords. Connector spring machines can meet the manufacturing needs of high-precision and high-efficiency connectors in the electronics industry.

2. Communication industry: In communication equipment, connector springs are used in key links such as signal transmission and power connection. Connector spring machines provide reliable and stable connector manufacturing solutions for the communication industry.

3. Automobile industry: With the development of automobile intelligence and electrification, the demand for connectors continues to increase. Connector spring machines play an important role in the field of automobile manufacturing and provide high-quality connectors for automobile electrical systems.

IV. Future development trend of connector spring machines

1. Intelligence: With the continuous development of artificial intelligence technology, connector spring machines will achieve a higher degree of intelligence. By introducing advanced technologies such as machine learning and visual recognition, the machine can automatically adjust processing parameters and optimize the processing process to achieve more efficient and precise production.

2. Flexibility: In the future, connector spring machines will pay more attention to flexible production. Through modular design, rapid mold change and other technical means, the machine can quickly adapt to the manufacturing needs of connector springs of different specifications and materials, and improve production efficiency and flexibility.

3. Green and environmental protection: With the continuous improvement of environmental awareness, connector spring machines will pay more attention to environmental protection and energy saving. Green manufacturing and sustainable development can be achieved through measures such as optimizing the processing process, reducing energy consumption, and reducing waste emissions.

4. Customization: With the diversification of market demand, connector spring machines will pay more attention to customized production. Through customized services, machines can meet customers' special needs for connector springs and improve market competitiveness.

In summary, as a highly specialized production equipment, connector spring machines play an important role in modern precision manufacturing. With the continuous development of technology and the continuous changes in market demand, connector spring machines will continue to develop in the direction of intelligence, flexibility, green environmental protection and customization, providing strong support for the transformation and upgrading of the manufacturing industry.