In the field of modern industrial manufacturing, the copper busbar bending machine for power control cabinets is an efficient and precise processing equipment, and its importance is self-evident. As an indispensable part of the power control cabinet, the processing quality and efficiency of the copper busbar directly affect the stability and reliability of the entire power system. This article will deeply explore the technical characteristics, application fields, operation points and future development trends of the copper busbar bending machine for power control cabinets.

1. Technical characteristics

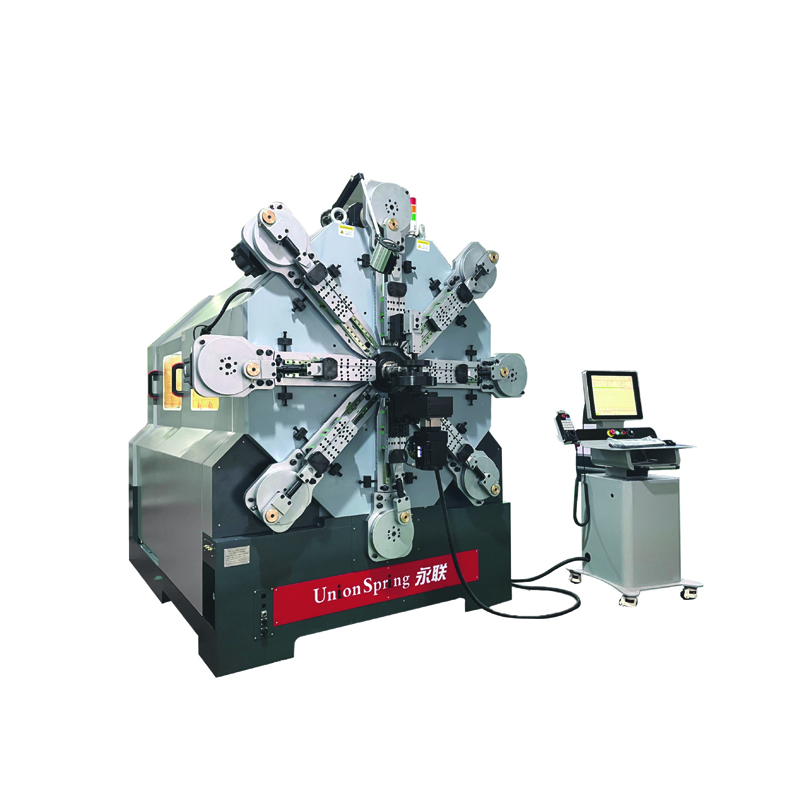

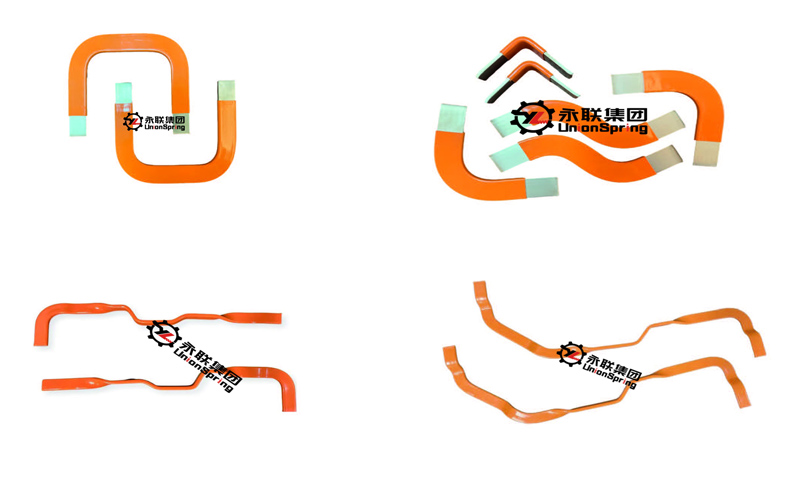

The copper busbar bending machine for power control cabinets adopts advanced CNC technology and has the characteristics of high precision, high efficiency and high degree of automation. It is made of high-strength alloy materials to ensure the stability and durability of the equipment. At the same time, the equipment is also equipped with a variety of bending molds to meet the bending needs of copper busbars of different specifications and angles. During the processing, the copper busbar bending machine for power control cabinets can achieve precise control, ensure the accuracy of bending angles and sizes, and greatly improve the processing quality.

2. Application fields

The copper busbar bending machine for power control cabinets is widely used in the power control cabinet manufacturing field in power, metallurgy, chemical industry, petroleum, transportation and other industries. In the power system, copper busbar is the carrier of power transmission, and its processing quality and efficiency directly affect the stability and reliability of the entire system. The copper busbar bending machine of the power control cabinet can meet the needs of different industries for copper busbar processing, and provide a strong guarantee for the stable operation of the power system.

III. Key points of operation

The key points of the copper busbar bending machine of the power control cabinet mainly include the following aspects:

1. Equipment debugging: Before formal use, the equipment needs to be fully debugged and inspected to ensure that the equipment is in the best working condition.

2. Material preparation: According to the processing requirements, prepare copper busbar materials of corresponding specifications and lengths, and perform necessary pretreatment.

3. Mold selection: Select a suitable bending mold according to the processing requirements and install it on the equipment.

4. Parameter setting: Set the bending angle, bending speed and other parameters of the equipment according to the processing requirements.

5. Start processing: Place the copper busbar on the equipment and start the equipment for bending processing. During the processing, pay close attention to the operating status and processing quality of the equipment, adjust parameters and correct errors in time.

6. Quality inspection: Conduct quality inspection on the processed copper busbar to ensure that it meets the processing requirements.

IV. Future development trends

With the continuous development and innovation of industrial manufacturing technology, the copper busbar bending machine of the power control cabinet is also constantly upgraded and improved. In the future, the development trend of the copper busbar bending machine of the power control cabinet is mainly reflected in the following aspects:

1. Intelligence: By introducing advanced technologies such as artificial intelligence and the Internet of Things, the intelligent control and management of equipment can be realized to improve processing efficiency and quality.

2. Customization: According to the needs of different industries and different customers, customized copper busbar bending solutions are provided to meet personalized needs.

3. Environmental protection and energy saving: Optimize the equipment structure, adopt environmentally friendly materials and energy-saving technologies, and reduce equipment energy consumption and environmental pollution.

4. Automation: Improve the degree of automation of the equipment, reduce manual intervention and operation difficulty, and reduce labor costs.

5. Diversification: Expand the application field and function of the equipment, achieve diversified development, and meet the needs of different industries for copper busbar processing.

In short, as one of the important equipment in the field of modern industrial manufacturing, the power control cabinet copper busbar bending machine's technical characteristics, application fields, operation points and future development trends are worthy of our attention and discussion. With the continuous advancement and innovation of technology, the power control cabinet copper busbar bending machine will make greater contributions to the stable operation of the power system and the development of the industrial manufacturing field.