In the field of electronic manufacturing, common mode inductor winding machines play an indispensable role as a key equipment. With its unique working principle and excellent performance, it plays a vital role in the manufacturing process of inductors. This article will conduct an in-depth discussion on the principles, characteristics, applications and market prospects of common mode inductor winding machines, and provide readers with a comprehensive analysis of the mystery of this equipment.

First, let’s understand the working principle of common mode inductor winding machine. Common mode inductor winding machines use the principle of electromagnetic induction to wind wires into inductors. During the manufacturing process, wire is precisely wound into one or more coils, which are then wrapped in magnetic material to form an inductor with specific electrical properties. The common mode inductor winding machine achieves precise manufacturing of inductors by precisely controlling the winding speed and winding direction of the wire.

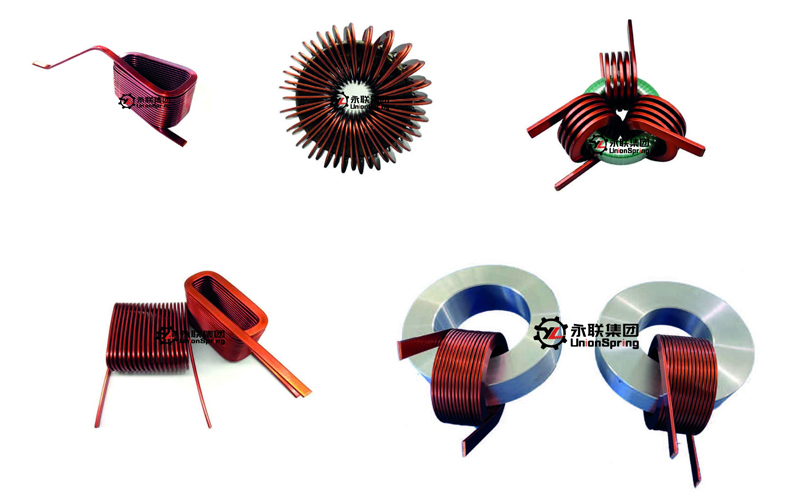

Common mode inductor winding machines have a series of notable features. First of all, it can effectively suppress common-mode interference and improve the signal's anti-interference performance. This is because during operation, the common-mode inductor attenuates interference signals by generating magnetic fields that cancel each other out. Secondly, common mode inductors have good temperature stability and can maintain stable performance over a wide temperature range. In addition, due to the toroidal core design, common mode inductors have the advantages of small size and light weight, making them easy to install and use. At the same time, through the cooperation of different manufacturing processes and the number of coil turns, common mode inductors can exhibit different impedance characteristics to meet the filtering requirements of different bands.

However, common mode inductor winding machines also have some shortcomings. First, its production cost is relatively high, mainly due to the precision winding and core manufacturing processes required. In addition, with the continuous development of electronic manufacturing technology, the performance requirements for inductors are also constantly increasing, which places higher requirements on the technology and performance of common mode inductor winding machines.

In terms of application fields, common mode inductor winding machines are widely used in the manufacturing process of electronic components, such as power supplies, inverters, converters and other equipment. These devices require high-performance inductors to ensure stable and reliable operating performance. Therefore, common mode inductor winding machines have broad market prospects in the field of electronic component manufacturing.

With the continuous development of the global electronics manufacturing industry, the market demand for common mode inductor winding machines continues to grow. Especially in the Asia-Pacific region, as an important area of electronic manufacturing, the demand for common mode inductor winding machines is particularly strong. In addition, the electronic manufacturing industry in developed regions such as Europe and North America is also growing, and the demand for common mode inductor winding machines is also gradually increasing.

However, in the face of fierce market competition and changing market demands, common mode inductor winding machine manufacturing companies need to continue to innovate and progress to improve the technical level and performance stability of their products. At the same time, it is also necessary to pay attention to industry development trends and market dynamics, and promptly adjust product structure and market strategies to adapt to changing market demands.

In short, as a key equipment in the field of electronic manufacturing, common mode inductor winding machine plays an important role in the manufacturing process of inductors. Although there are some shortcomings, with the continuous advancement of technology and the continuous expansion of the market, its application prospects are still very broad. We expect that common mode inductor winding machines will continue to play a greater role in the future and contribute more to the development of the electronics manufacturing industry.