As a key equipment widely used in the electronics manufacturing industry, the importance of rectangular coil winding machine is self-evident. It can not only efficiently complete tasks such as coil winding, welding and cutting, but also greatly improve product quality and production efficiency. This article will deeply explore the working principle, application field, development trend and market prospects of rectangular coil winding machine, and provide readers with a comprehensive and in-depth understanding.

First, let's understand the working principle of rectangular coil winding machine. It uses a motor to drive the winding shaft to rotate, and at the same time controls the tension and winding speed of the wire, so that the wire can be evenly wound on the rectangular coil skeleton to form the required coil structure. In this process, the control system plays a vital role. It needs to accurately adjust the parameters such as the speed, direction and tension of the winding shaft according to the parameter requirements of the coil to ensure the quality and consistency of the coil.

The application field of rectangular coil winding machine is very wide. In the manufacture of electronic components, it can be used to wind components such as inductors, capacitors, resistors, etc. to ensure the stable and reliable performance of these components. In the manufacture of automotive wiring harnesses, rectangular coil winding machines can accurately wind the internal wires of the car to ensure the stability and safety of the automotive circuit. In the field of home appliance manufacturing, the wires used inside electrical products such as air conditioners, refrigerators, washing machines, etc. also require rectangular coil winding machines to complete the winding work. In addition, in the manufacturing of LED lamps, rectangular coil winding machines also play an indispensable role.

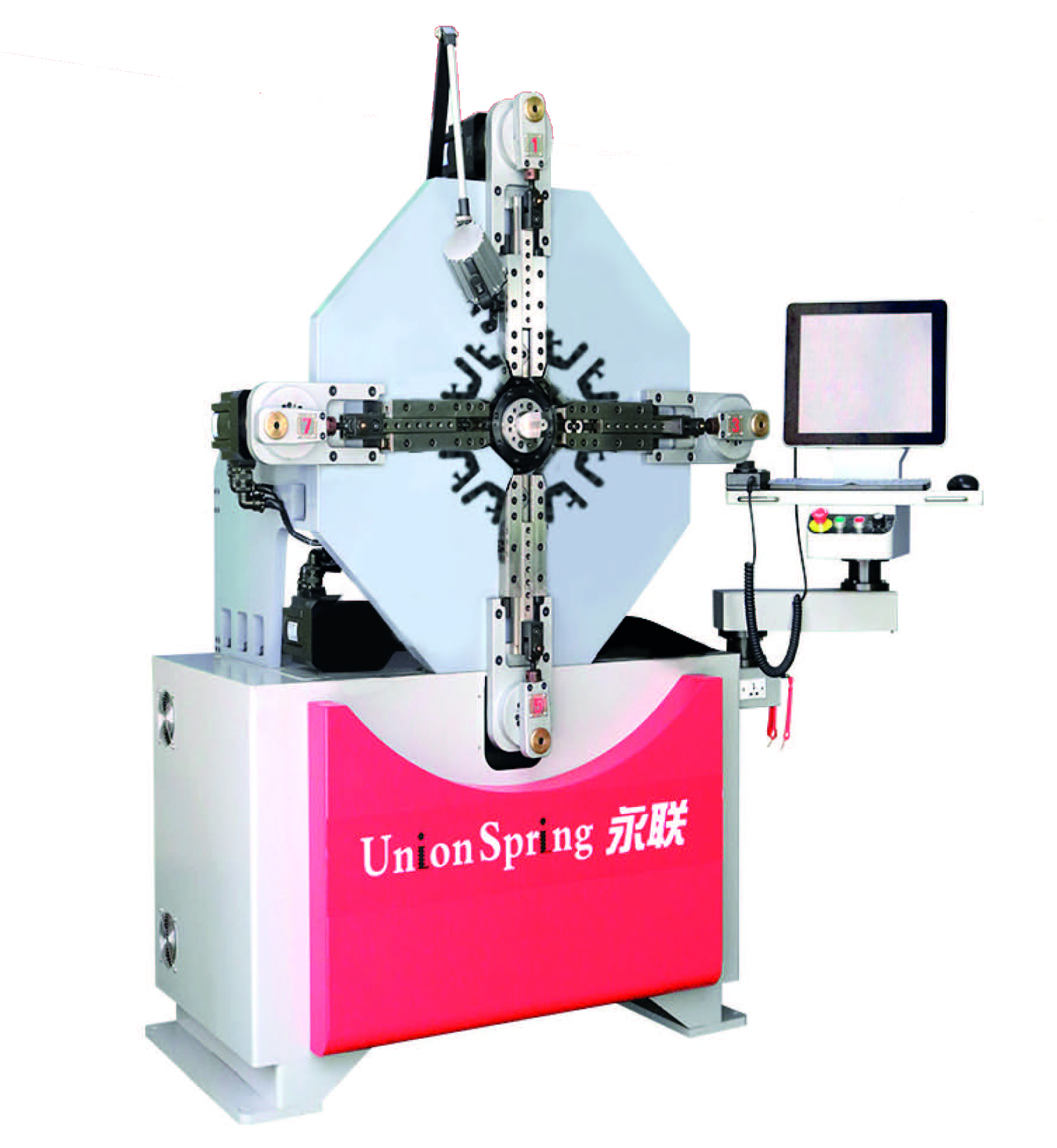

With the continuous development of science and technology, rectangular coil winding machines are also constantly innovating and upgrading technology. On the one hand, the new rectangular coil winding machine is more compact in structure and more convenient to operate, which greatly improves the ease of use and reliability of the equipment. On the other hand, the trend of intelligence and automation is also fully reflected in the rectangular coil winding machine. By introducing advanced control systems and sensor technology, the rectangular coil winding machine can achieve more accurate parameter adjustment and fault detection, further improving production efficiency and product quality.

From the perspective of market prospects, rectangular coil winding machines have broad development space. With the rapid development of the electronics manufacturing industry, the demand for coil winding equipment is also increasing. At the same time, with the rise of emerging industries such as new energy vehicles and smart homes, the demand for rectangular coil winding machines will also increase further. In addition, with the continuous improvement of the country's requirements for environmental protection and energy conservation, the advantages of rectangular coil winding machines in energy conservation and emission reduction will also be more widely used and recognized.

However, in the face of fierce market competition and changing market demands, rectangular coil winding machine manufacturers also need to continue to innovate and upgrade to adapt to market development and changes. On the one hand, companies need to strengthen technological research and development and innovation, and continuously improve the performance and quality of equipment; on the other hand, companies also need to pay close attention to market trends and customer needs, and adjust product structure and market strategies in a timely manner to maintain competitive advantages.

In short, as an important electronic manufacturing equipment, rectangular coil winding machines play an indispensable role in the electronic manufacturing industry. With the continuous advancement of technology and the continuous expansion of market demand, rectangular coil winding machines will usher in broader development space and opportunities. We have reason to believe that in the future development, rectangular coil winding machines will continue to make greater contributions to the prosperity and development of the electronic manufacturing industry.