In modern industrial production, the copper bar bending machine for power control cabinet plays a pivotal role. As a professional equipment, it is widely used in the fields of electricity, electronics, communications, machinery, etc., providing efficient and accurate solutions for the manufacture of various control cabinets. This article will discuss in detail the working principle, functional characteristics, application fields and future development trends of the copper bar bending machine for power control cabinet, aiming to help readers better understand and use this equipment.

First, let's take a look at the working principle of the copper bar bending machine for power control cabinet. The equipment is mainly driven by a motor to realize the bending processing of the copper bar. During the operation, the operator puts the copper bar into the fixture of the equipment, sets the parameters such as the bending angle and radius, and starts the equipment. The equipment will accurately bend the copper bar through the motor-driven bending die according to the set parameters. Throughout the process, the equipment has the characteristics of high degree of automation and high processing accuracy, which can greatly improve production efficiency and product quality.

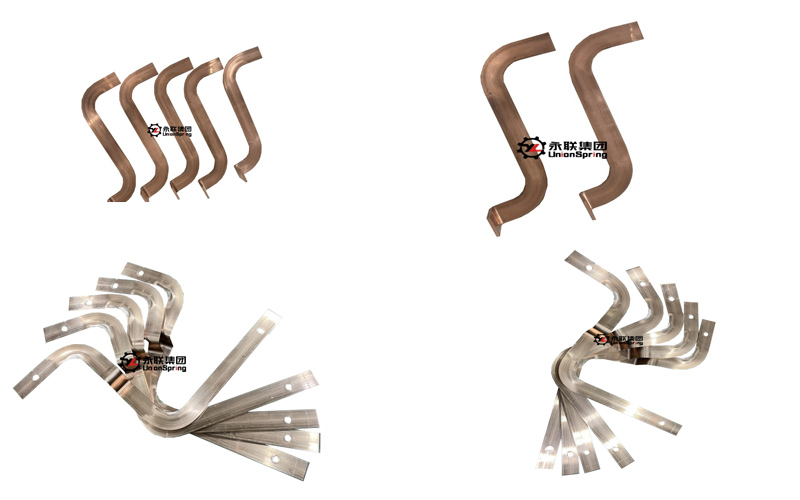

In terms of functional characteristics, the copper bar bending machine for power control cabinet has many advantages. First of all, it has the function of adjusting multiple bending angles and radii, which can adapt to the processing of copper bars of different specifications and requirements. Secondly, the equipment uses high-precision sensors and control systems, which can achieve precise bending processing and ensure product quality. In addition, the equipment is easy to operate, safe and reliable, and easy to maintain, which can meet the needs of different users.

In terms of application areas, the copper bar bending machine for power control cabinets is widely used in power, electronics, communications, machinery and other fields. In the power industry, it is used to bend copper bars for various high and low voltage control cabinets; in the electronics industry, it is used to bend copper bars for circuit boards, power supplies and other equipment; in the communications industry, it is used to bend copper bars for communication equipment, base stations and other equipment; in the machinery industry, it is used to bend copper bars for various mechanical equipment. It can be said that the copper bar bending machine for power control cabinets plays an irreplaceable role in all fields.

In the future, with the continuous development of industrial automation, the copper bar bending machine for power control cabinets will develop in a more intelligent and efficient direction. On the one hand, the equipment will adopt more advanced sensors and control systems to achieve more precise bending processing and automated operation; on the other hand, the equipment will pay more attention to environmental protection and energy saving, adopt more environmentally friendly materials and processes, and reduce energy consumption and emissions. In addition, with the continuous development of artificial intelligence technology, the power control cabinet copper bar bending machine will also achieve more intelligent operation and maintenance, improve production efficiency and reduce labor costs.

In short, as an efficient and precise processing equipment, the power control cabinet copper bar bending machine plays an important role in industrial production. With the continuous advancement of technology and the continuous expansion of application fields, it is believed that it will provide more high-quality and efficient solutions for more industries. At the same time, we also look forward to the future power control cabinet copper bar bending machine to achieve greater breakthroughs and innovations in intelligence, environmental protection and energy saving, and contribute more to the sustainable development of industrial production.