In the field of electric vehicle manufacturing, the EV battery pack is the core component of the power system, and its quality and performance directly affect the performance and service life of the whole vehicle. The connecting busbar inside the battery pack is the key to ensure stable and efficient power transmission between battery cells. Therefore, the performance and precision requirements of the busbar bending machine are extremely high. This article will introduce in detail the working principle, characteristics, application fields and future development trends of the EV battery pack connecting busbar bending machine.

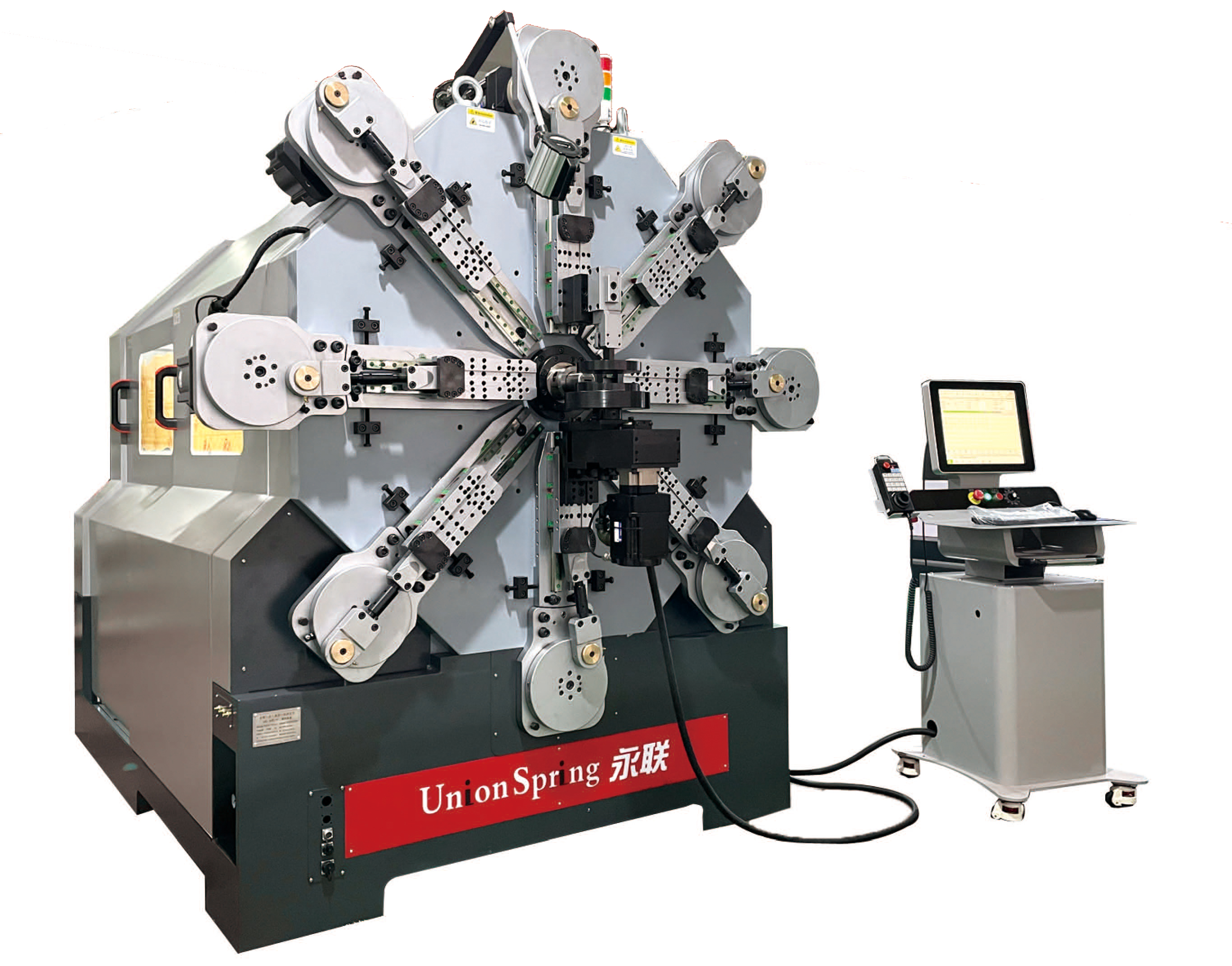

First, let's take a look at the working principle of the busbar bending machine. The busbar bending machine is a device specially used for bending and forming busbar materials. The bending action is completed by driving the blade through a hydraulic cylinder or a cylinder. During the processing, the busbar material is placed on the machine workbench, fixed by a positioning device, and then bent according to the preset parameters. In order to ensure the processing accuracy and quality, the busbar bending machine needs to be equipped with high-precision molds and control systems to ensure that the angle and position of each bend can meet the design requirements.

Compared with traditional bending equipment, the EV battery pack connecting busbar bending machine has many characteristics. First of all, it uses advanced CNC technology, which can realize automated and intelligent processing processes, greatly improving production efficiency. Secondly, the equipment has a high degree of processing accuracy and stability, which can ensure the reliability and safety of busbar connection. In addition, the busbar bending machine also has the advantages of easy operation and convenient maintenance, which reduces the labor intensity of operators and increases the service life of the equipment.

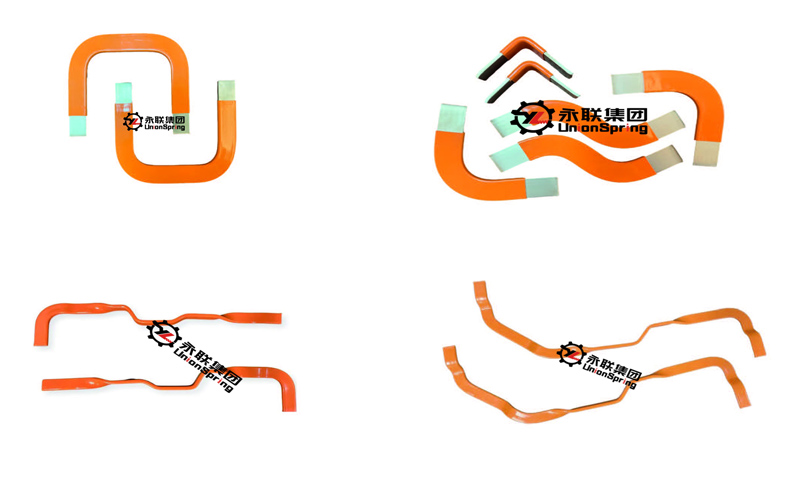

In terms of application areas, EV battery pack connection busbar bending machines are widely used in the battery pack manufacturing process in new energy fields such as electric vehicles and energy storage power stations. With the rapid development of the new energy vehicle market, the requirements for battery pack performance and quality are constantly increasing. As one of the key equipment, the market demand for busbar bending machines has also shown a rapid growth trend.

In the future, with the continuous innovation and progress of new energy vehicle technology, busbar bending machines will also face more development opportunities and challenges. On the one hand, with the continuous optimization and upgrading of battery pack structure, busbar bending machines need to continuously improve their processing accuracy and stability to meet the higher requirements of battery pack manufacturing. On the other hand, with the development of intelligent manufacturing and digital factories, busbar bending machines also need to gradually realize intelligence, automation and digitalization, achieve seamless docking with the entire production line, and improve production efficiency and quality.

In addition, busbar bending machines also have broad development space in research and development and innovation. For example, by introducing advanced sensors and detection technologies, real-time monitoring and quality control of the busbar bending process can be achieved; by optimizing the equipment structure and control system, energy consumption and noise can be reduced, and the environmental performance of the equipment can be improved; by developing new molds and processing technologies, the application field and processing range of the busbar bending machine can be expanded.

In short, as one of the key equipment in the field of new energy vehicle manufacturing, the performance and quality of the EV battery pack connecting busbar bending machine are of great significance to ensuring the performance and safety of the battery pack. With the rapid development of the new energy vehicle market and the continuous advancement of technology, the busbar bending machine will also usher in more development opportunities and challenges. We believe that in the near future, the busbar bending machine will play a more important role in the field of new energy vehicle manufacturing and make greater contributions to the sustainable development of the new energy vehicle industry.