The power control cabinet copper bar bending machine, as an important power equipment processing tool, is widely used in the production process of various types of electrical control cabinets, distribution boxes and other equipment. As an important component of electrical connections, the processing quality of copper bars is directly related to the performance and safety of electrical equipment. Therefore, the design and manufacturing of copper bar bending machines play a vital role in the production of electrical equipment.

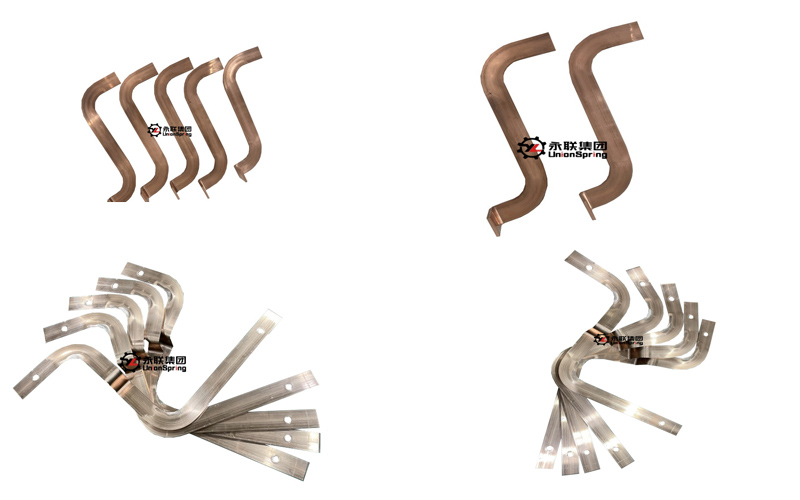

First of all, the main function of the power control cabinet copper bar bending machine is to perform precise bending operations on the copper bar. As a conductive material, copper busbar has excellent electrical conductivity and high mechanical strength, so it is widely used in electrical equipment. However, copper bars come in various shapes and sizes and require custom processing based on specific equipment needs. The copper bar bending machine can achieve precise bending of copper bar through precise mechanical structure and control system to meet the needs of various complex shapes and sizes.

Secondly, the power control cabinet copper bar bending machine has efficient and stable production capacity. In the production process of electrical equipment, the processing of copper strips is an important link. Traditional processing methods often require manual operations, which are inefficient and error-prone. The copper bar bending machine can achieve efficient and stable copper bar processing through an automated control system and mechanical structure, greatly improving production efficiency and reducing production costs.

In addition, the power control cabinet copper bar bending machine is also easy to operate, safe and reliable. The control system of the copper bar bending machine adopts a humanized design, and the operation interface is simple and clear, allowing operators to easily master operating skills. At the same time, the copper bar bending machine strictly follows safety regulations during the design and manufacturing process to ensure the safety and stability of the equipment.

In practical applications, power control cabinet copper bar bending machines are widely used in the production process of various types of electrical control cabinets, distribution boxes and other equipment. For example, in power systems, electrical control cabinets are important equipment for distribution, control and protection of electrical energy. As a key component in the electrical control cabinet, the processing quality of copper bars is directly related to the performance and safety of the electrical control cabinet. By using the copper bar bending machine, the copper bar can be bent accurately to meet the complex shape and size requirements of the electrical control cabinet and improve the overall performance of the electrical equipment.

In addition, with the continuous advancement of science and technology and the continuous development of electrical equipment, power control cabinet copper bar bending machines are also constantly upgraded and improved. The new copper bar bending machine adopts advanced CNC technology, servo drive technology, etc. to achieve higher processing accuracy, more stable production capacity and more flexible operation methods. At the same time, with the increasing awareness of environmental protection, copper bar bending machines are paying more attention to environmental protection and energy saving in the design and manufacturing process to meet the needs of sustainable development.

In short, the power control cabinet copper bar bending machine is one of the important equipment in the production process of electrical equipment. Its design, manufacturing and application play a vital role in the performance and safety of electrical equipment. With the continuous advancement of science and technology and the continuous development of electrical equipment, copper bar bending machines will continue to be upgraded and improved to provide more efficient, stable, safe and environmentally friendly solutions for the production of electrical equipment.