As a special industrial equipment, copper and aluminum busbar bending machines are widely used in electric power, electronics, communications, construction and other fields. Its main function is to precisely bend copper, aluminum and other metal busbars to meet the shape and size requirements of different projects. This article will introduce in detail the structure, working principle, application fields, operation and maintenance of the copper and aluminum busbar bending machine.

1. Structure and working principle of copper and aluminum busbar bending machine

The copper and aluminum busbar bending machine mainly consists of a frame, a workbench, a bending mechanism, a control system and other parts. The rack is the supporting structure of the entire equipment, and the workbench is used to place the busbars to be processed. The bending mechanism is the core component of the copper-aluminum busbar bending machine, including a bending knife, a bending shaft, a transmission mechanism, etc., and realizes the bending operation of the busbar through precise transmission and control. The control system is responsible for the operation control of the entire equipment and the management of the operating interface.

In terms of working principle, the copper and aluminum busbar bending machine mainly uses a combination of mechanical transmission and hydraulic transmission. The motor drives the transmission mechanism to make the bending knife reciprocate on the bending axis, thereby realizing the bending of the busbar. At the same time, the hydraulic system provides sufficient pressure and speed to ensure a smooth and accurate bending process.

2. Application areas of copper and aluminum busbar bending machines

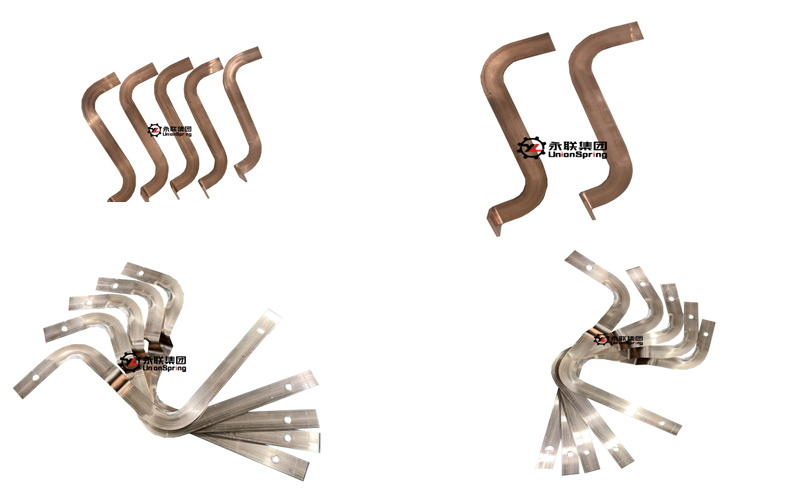

Copper and aluminum busbar bending machines are widely used in many fields. In the power field, it is used to make the busbar connection parts of electrical equipment such as high and low voltage switch cabinets and bus ducts. In the electronics field, copper and aluminum busbar bending machines can be used to produce pins and connecting wires for various electronic components. In the field of communications, busbar bending machines can be used to make cable and line connection parts of communications equipment. In addition, in the construction field, copper and aluminum busbar bending machines are also used to make busbar connection parts for building electrical equipment.

3. Operation and maintenance of copper and aluminum busbar bending machines

Operating a copper and aluminum busbar bending machine requires certain professional skills and experience. Operators should be familiar with the structure and working principles of the equipment and master the correct operating methods. During the operation, you should pay attention to safety matters, such as wearing protective glasses, gloves and other personal protective equipment to avoid accidents. At the same time, regular inspection and maintenance of equipment are also important measures to ensure normal operation of equipment and extend its service life.

In terms of maintenance, all parts of the copper-aluminum busbar bending machine should be inspected and cleaned regularly to ensure that the equipment is in good working condition. Consumable parts and wear parts should be replaced and repaired in time to avoid affecting the performance and accuracy of the equipment. In addition, the lubrication system of the equipment should be maintained regularly to ensure that the equipment is fully lubricated and cooled during operation.

4. Development Trend of Copper and Aluminum Busbar Bending Machines

With the continuous advancement of science and technology and the rapid development of industry, copper and aluminum busbar bending machines are also constantly upgraded and improved. In the future, the development trend of copper and aluminum busbar bending machines will be mainly reflected in the following aspects:

1. Intelligentization: By introducing advanced control systems and sensor technologies, we can realize the automation and intelligent operation of equipment and improve production efficiency and product quality.

2. High precision: As industrial precision requirements become higher and higher, copper and aluminum busbar bending machines need to continuously improve their processing accuracy and stability to meet the high-precision requirements for busbar shape and size in different fields.

3. Energy saving and environmental protection: With the increasing awareness of environmental protection, copper and aluminum busbar bending machines need to adopt more energy-saving and environmentally friendly power systems and control technologies to reduce energy consumption and waste emissions.

4. Multifunctionality: In the future, copper and aluminum busbar bending machines may incorporate more functions and features, such as automatic feeding, automatic detection, etc., to achieve more efficient and diversified busbar processing needs.

In short, as an important industrial equipment, the copper and aluminum busbar bending machine plays an irreplaceable role in various fields. With the continuous advancement of technology and the expansion of application fields, copper and aluminum busbar bending machines will usher in broader development space and more severe challenges.