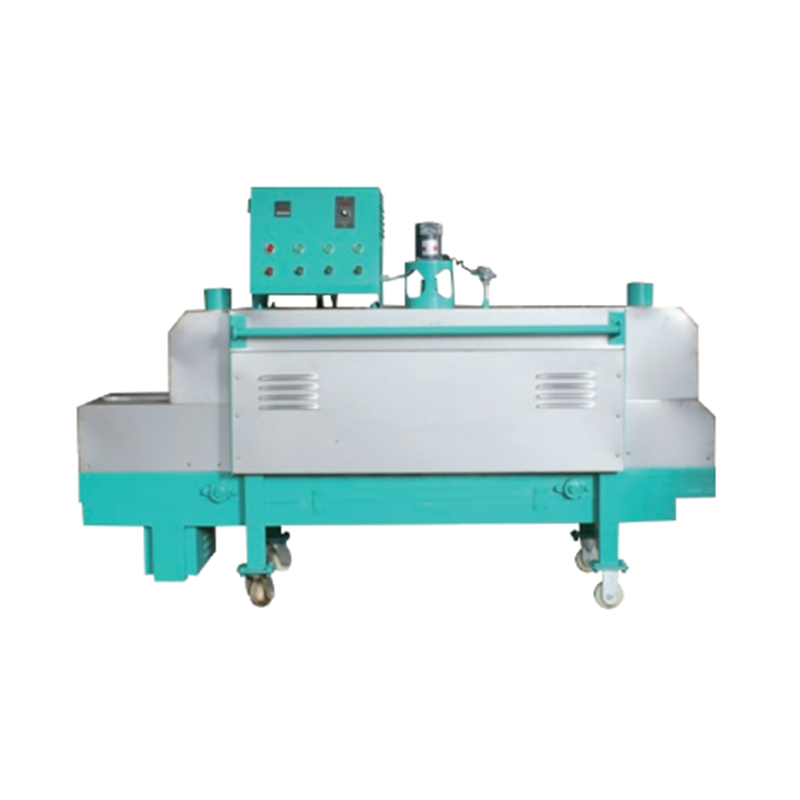

Products Description

1.Continuous hot air tempering furnace (mesh belt furnace), also known as conveyor-type electric control tempering furnace (mesh belt furnace), using imported PID intelligent temperature controller and complete automatic control system, within 500 ℃ furnace temperature, according to The process requires any temperature to be set, and the control accuracy is ± 3 ° C. Equipped with a hot air stirring device, the furnace temperature is accurately balanced, and the quality of the tempered workpiece is stable and reliable.

2.Stainless steel mesh belt runs smoothly with stepless speed regulation. Continuous automatic operation can greatly improve labor productivity and reduce labor intensity.

3.The structure is novel, adopting all-fiber furnace lining, fast heating, low power consumption, high heat utilization rate, good energy saving effect, power consumption after constant temperature does not exceed 50% of rated power.

4.It is easy to operate, safe and reliable, does not require the use of sodium nitrite, the site is clean, and there is no environmental pollution.

5.The model has complete specifications, long service life, convenient maintenance, low investment, and low price, which is less than 30% of similar imported products. It can meet the thermal aging treatment requirements of various bombs and chains. It is an ideal heat treatment equipment for spring and chain industries.

Technical parameter

MODEL | US-H210 | US-H315 | US-W426 |

Power | 8KW | 16KW | 26KW |

Max. Temperature | 500℃ | 500℃ | 500℃ |

Temper wire diameter range | 0.1-6.0mm | 0.1-6.0mm | 0.1-6.0mm |

Range of tempering time | 2.5-40MIN | 4-50MIN | 6-60MIN |

Output of tempering pieces | 18-25kg/h | 35-50kg/h | 60-80kg/h |

Dimension (LxWxH) | 2000*750*1300mm | 2600*850*1320mm | 3300*950*1400mm |

The specifications and features are subject to change without notice.