In the field of precision machining in modern manufacturing, camless spring machines have gradually emerged with their unique advantages and become an important tool for the transformation and upgrading of many spring production companies. This equipment not only greatly improves production efficiency, but also significantly improves the stability and consistency of product quality, bringing revolutionary changes to the spring manufacturing industry. Below, we will delve into the technical principles, application advantages, market status and future development trends of camless spring machines.

Technical Principles and Innovation

The camless spring machine, as the name suggests, abandons the design of traditional machinery that relies on cam mechanisms for drive, and instead adopts advanced CNC technology and servo motor drive systems. This revolution fundamentally changed the control method and processing accuracy of spring production. Through high-precision servo motors and precise transmission mechanisms, the camless spring machine can achieve precise control of the spring forming process, and can easily handle small changes in wire diameter or complex adjustments in shape.

Its core lies in its CNC system, which integrates advanced programming software and algorithms, allowing the operator to directly input the specifications of the spring on the touch screen, such as wire diameter, outer diameter, number of turns, pitch, etc., and then the system will adjust the spring according to these parameters. The parameters automatically calculate the optimal processing path and speed, and are accurately executed by the servo motor. This "intelligent" production method not only simplifies the operating process and reduces the skill requirements for operators, but also greatly improves production efficiency and product accuracy.

Significant application advantages

1. High production efficiency: The camless spring machine adopts continuous processing mode, which reduces mold change and debugging time and greatly improves production efficiency. Compared with traditional equipment, its production speed can be increased several times or even dozens of times.

2. High product precision: Thanks to the precise control of the servo motor and the intelligent algorithm of the CNC system, the camless spring machine can produce extremely high-precision spring products to meet the requirements of spring quality in high-end fields such as aerospace, automobile manufacturing, and medical equipment. strict requirements.

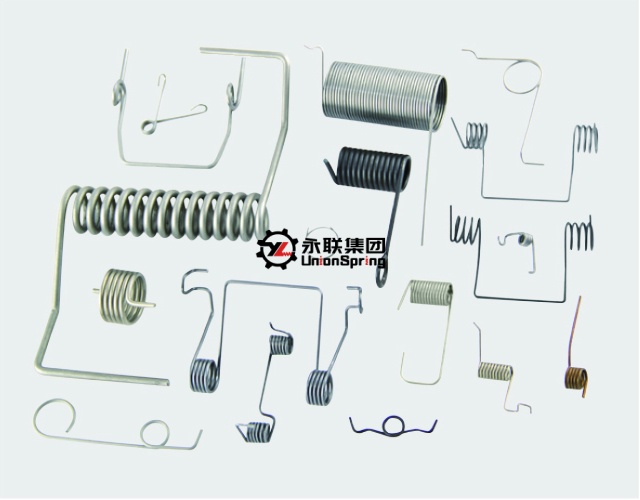

3. High flexibility: Traditional cam spring machines are limited by the shape and quantity of cams, making it difficult to process complex and changeable spring shapes. The camless design breaks this limitation and can easily process various complex springs through programming, greatly improving production flexibility.

4. Low maintenance cost: The camless structure reduces mechanical wear and failure points, reducing daily maintenance costs. At the same time, its high degree of intelligence, fault self-checking and remote diagnosis functions further reduce maintenance difficulty and costs.

Market status and prospects

With the rapid development of the manufacturing industry and the acceleration of intelligent transformation, the market demand for camless spring machines continues to grow. Especially in the automotive, electronics, communications, medical equipment and other industries, the demand for high-quality, high-precision springs is increasingly strong, providing a broad development space for camless spring machines.

At present, many well-known domestic and foreign companies have set foot in the field of camless spring machines, continuously improving their market competitiveness through technological innovation and brand building. At the same time, with the application of new technologies such as intelligent manufacturing and the industrial Internet, camless spring machines are gradually developing in the direction of intelligence, networking, and service, providing users with more efficient, convenient, and personalized solutions.

Future trends

Looking to the future, the development of camless spring machines will show the following trends:

1. More intelligent: As technologies such as artificial intelligence and big data continue to mature, camless spring machines will achieve a higher degree of intelligence, including intelligent programming, intelligent diagnosis, intelligent optimization and other functions, further improving production efficiency and products. quality.

2. More customized: In response to the individual needs of different industries and customers, the camless spring machine will provide more customized solutions, including processing of special materials, design of special shapes, etc., to meet the diversified needs of the market.

3. More green: With the enhancement of environmental awareness and the popularization of green manufacturing concepts, camless spring machines will pay more attention to environmental protection and sustainable development in terms of material selection, energy consumption, waste disposal, etc.

4. More networked: With the help of industrial Internet technology, camless spring machines will achieve seamless docking and collaborative production with upstream and downstream enterprises, forming a more efficient, flexible and intelligent supply chain system.

To sum up, the camless spring machine, as one of the important tools in modern manufacturing industry, is leading the reform and development of the spring production industry with its unique advantages. With the continuous advancement of technology and the continuous expansion of the market, we have reason to believe that camless spring machines will play a more important role in the future and contribute more to the intelligent transformation and high-quality development of the manufacturing industry.