With the rapid development of modern manufacturing industry, various precision processing equipment emerges in an endless stream. Among them, flat copper wire bending machine, as one of the important equipment for metal wire processing, plays an indispensable role in the fields of electronics, electrical appliances, automobiles, aerospace, etc. This article will conduct an in-depth discussion and analysis on the working principle, structural characteristics, application fields, operating skills and future development trends of flat copper wire bending machine.

1. Working principle of flat copper wire bending machine

The flat copper wire bending machine is mainly driven by a motor, and after a series of deceleration and transmission mechanisms, the rotary motion is converted into linear motion, thereby driving the bending arm to complete the bending action. During the bending process, the precise control system equipped with the bending machine can ensure the accuracy and stability of the bending angle and meet the requirements of different products for bending accuracy.

2. Structural characteristics of flat copper wire bending machine

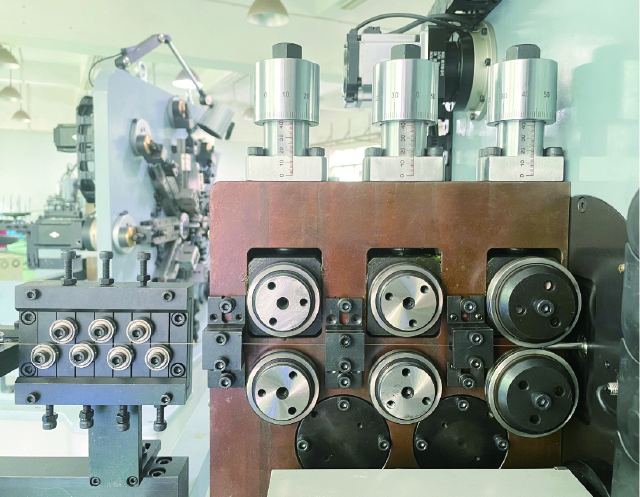

The flat copper wire bending machine usually uses high-strength steel as the fuselage frame to ensure the stability and durability of the equipment. The bending arm part is made of high-quality alloy material, which has excellent strength and toughness after precision processing and heat treatment. In addition, the bending machine is also equipped with advanced control systems and detection devices, such as touch screens, servo motors, encoders, displacement sensors, etc., to achieve precise control and real-time monitoring of the bending process.

3. Application fields of flat copper wire bending machines

Flat copper wire bending machines are widely used in electronics, electrical appliances, automobiles, aerospace and other fields. In the electronics industry, flat copper wire bending machines are mainly used for the bending of various connectors, sockets, switches and other electronic components; in the electrical industry, bending machines are used to manufacture windings of various motors, transformers, relays and other electrical appliances; in the automotive and aerospace fields, flat copper wire bending machines are used to produce various sensors, controllers and other precision parts.

4. Operating skills of flat copper wire bending machines

Operating flat copper wire bending machines requires certain skills and methods. First of all, the operator should be familiar with the working principle and structural characteristics of the equipment, and understand the functions and operation methods of each component. Secondly, the stability and precision of the equipment should be maintained during operation to avoid damage to the equipment caused by excessive vibration and impact. At the same time, the equipment should be maintained regularly, and worn parts should be replaced in time to ensure the normal operation of the equipment.

In actual operation, the following points should also be noted:

1. Select appropriate bending molds and parameter settings according to product requirements to ensure the accuracy of bending angles and precision.

2. Before bending, check whether the quality and size of the material meet the requirements to avoid poor bending due to material problems.

3. During the bending process, pay attention to the deformation of the material, adjust the bending force and speed in time, and avoid excessive deformation or breakage of the material.

4. After the bending is completed, the product should be inspected for quality to ensure that the product meets the standards and customer requirements.

V. Future development trend of flat copper wire bending machine

With the transformation and upgrading of the manufacturing industry and the intelligent development, flat copper wire bending machines will also usher in new development opportunities and challenges. In the future, flat copper wire bending machines will pay more attention to the development of automation, intelligence and environmental protection. On the one hand, by introducing advanced automation control systems and robotics technology, the automated production and intelligent management of equipment can be realized; on the other hand, the environmental protection performance design of the equipment should be strengthened to reduce energy consumption and emissions in the production process and achieve green manufacturing.

In addition, with the continuous emergence of new materials and new processes, flat copper wire bending machines also need to be continuously updated to improve the processing capacity and adaptability of the equipment. For example, high-precision servo motors and encoder technology are used to improve bending accuracy and stability; new technologies such as laser cutting and plasma welding are introduced to achieve more complex bending processing and combinations.

In short, as one of the important equipment for metal wire processing, flat copper wire bending machines play an irreplaceable role in the manufacturing industry. In the future, with the transformation, upgrading and intelligent development of the manufacturing industry, flat copper wire bending machines will continue to usher in new development opportunities and challenges.