With the rapid development of modern industrial technology, energy storage cabinets are an indispensable part of the power system, and their safety and reliability are of great significance to ensuring power supply. In the production process of energy storage cabinets, copper busbar bending machine is an important processing equipment, and its performance directly affects the quality and performance of energy storage cabinets. This article will give a detailed introduction to the copper busbar bending machine of energy storage cabinets, including its working principle, structural characteristics, application fields and future development trends.

1. Working principle of copper busbar bending machine of energy storage cabinet

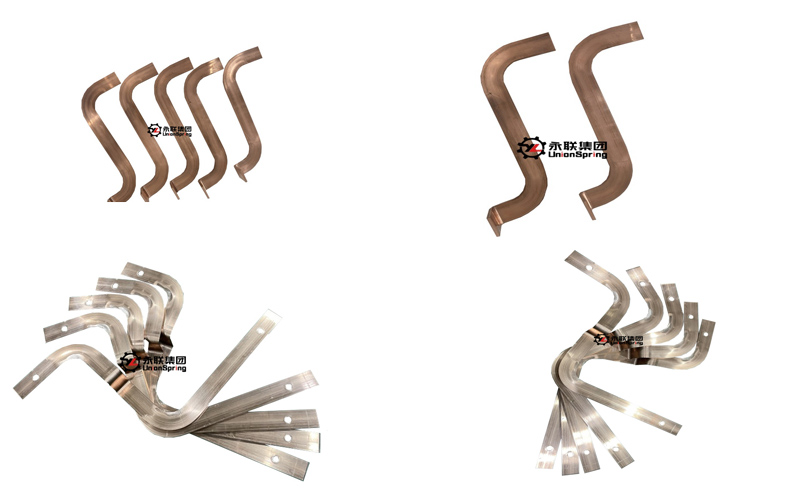

The copper busbar bending machine of energy storage cabinet mainly uses mechanical force to bend the copper busbar material according to the predetermined angle and shape. Its working principle is mainly based on the principle of lever and mechanical transmission. The transmission mechanism is driven by the motor to make the bending mold produce relative movement, thereby bending the copper busbar. During the bending process, the equipment ensures the accuracy of the bending angle and shape through a precise control system to meet the design requirements of the energy storage cabinet.

2. Structural characteristics of copper busbar bending machine for energy storage cabinet

Energy storage cabinet copper busbar bending machine is usually made of high-strength steel, with the characteristics of compact structure, good stability and strong bearing capacity. The equipment mainly includes frame, transmission mechanism, bending mold, control system and other parts. Among them, the frame, as the main part of the equipment, needs to withstand large bending force and impact force, so it is made of high-strength steel to ensure the stability and safety of the equipment. The transmission mechanism is responsible for driving the bending mold for relative movement, usually driven by high-precision servo motor and reducer to ensure bending accuracy and stability. The bending mold is the core component of the equipment, and its design and manufacturing accuracy directly affect the bending effect and equipment performance. The control system is responsible for the overall control and monitoring of the equipment, including motor control, position detection, angle adjustment and other functions to ensure the efficient operation and safe production of the equipment.

3. Application field of copper busbar bending machine for energy storage cabinet

Energy storage cabinet copper busbar bending machine is widely used in power system, new energy, communication and other fields. In the power system, energy storage cabinet is an important energy storage device, and its quality and performance are of great significance to ensure power supply. As an important component of the energy storage cabinet, the copper busbar bending accuracy and shape stability directly affect the performance and safety of the energy storage cabinet. Therefore, the copper busbar bending machine for energy storage cabinets has broad application prospects in the field of power systems. In addition, with the rapid development of new energy and communication technologies, the application of energy storage cabinets in these fields is becoming more and more extensive, and the market demand for copper busbar bending machines for energy storage cabinets is also increasing.

4. Future development trend of copper busbar bending machines for energy storage cabinets

With the continuous advancement of industrial technology and the continuous increase in market demand, copper busbar bending machines for energy storage cabinets are also constantly developing and innovating. In the future, copper busbar bending machines for energy storage cabinets will show the following development trends:

1. The degree of automation continues to improve: With the continuous development of automation technology, copper busbar bending machines for energy storage cabinets will achieve a higher degree of automation. By introducing advanced control systems and sensor technologies, the equipment can realize functions such as automatic detection, automatic adjustment, and automatic alarm, thereby improving the production efficiency and safety of the equipment.

2. Continuous improvement in accuracy and stability: With the continuous advancement of manufacturing technology, the accuracy and stability of copper busbar bending machines for energy storage cabinets will continue to improve. By optimizing the equipment structure and manufacturing process, the manufacturing accuracy and wear resistance of the bending mold are improved to ensure that the equipment can maintain stable performance during long-term use.

3. The level of intelligence continues to improve: With the continuous development of artificial intelligence technology, the energy storage cabinet copper bar bending machine will achieve a higher level of intelligence. By introducing technologies such as machine learning and big data analysis, real-time monitoring and predictive maintenance of the equipment operation status can be achieved, reducing equipment failure rate and maintenance costs.

4. Green environmental protection has become an important development direction: With the continuous improvement of environmental awareness, the energy storage cabinet copper bar bending machine will pay more attention to environmental protection factors in the design and manufacturing process. By adopting low-energy consumption, low-noise, and pollution-free manufacturing technology and materials, the impact of equipment on the environment can be reduced to achieve green production.

In summary, as an important processing equipment in the power system, the performance of the energy storage cabinet copper bar bending machine directly affects the quality and performance of the energy storage cabinet. In the future, with the continuous advancement of industrial technology and the continuous increase in market demand, the energy storage cabinet copper bar bending machine will continue to develop and innovate, providing more reliable and efficient guarantees for the safe and stable operation of the power system.