Spring machinery, as an important part of the industrial field, assumes the responsibility of providing key components for many industries. From automobiles, machinery, electronics to aerospace, springs are used everywhere, and spring machinery is the key equipment for manufacturing these high-precision springs. This article will delve into the working principle, application fields, technological development and future trends of spring machinery, hoping to provide readers with a comprehensive and in-depth understanding.

1. Working principle of spring machinery

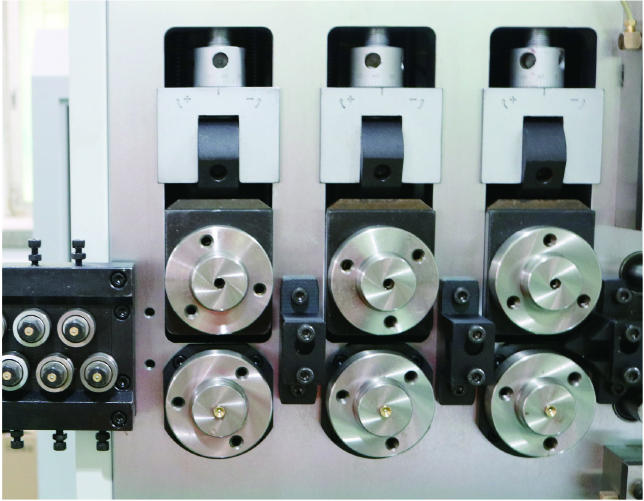

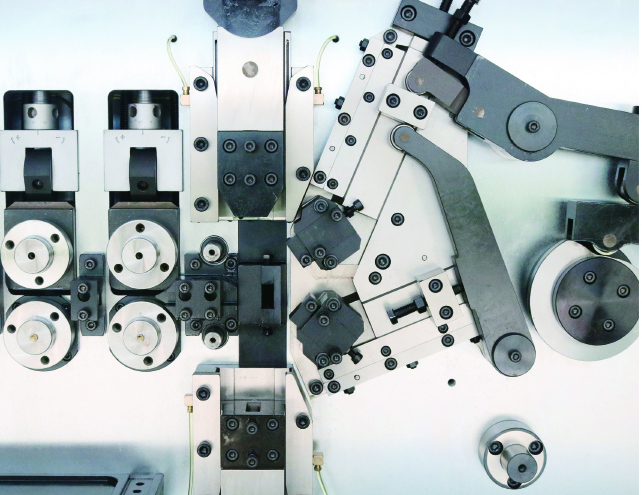

The working principle of spring machinery is mainly based on the principles of material mechanics and elastic mechanics. Through precise control systems and transmission mechanisms, spring machinery can process raw materials such as metal wires and plates into springs of various shapes and sizes. During the processing process, spring machinery needs to perform operations such as bending, compression, and stretching of materials to achieve the required spring properties.

2. Application fields of spring machinery

The application fields of spring machinery are very wide, covering almost all industries that require springs. In the automotive industry, spring machinery is used to produce key components such as automotive suspension systems and engine valve springs. In the machinery industry, spring machinery is used to manufacture various transmission devices, shock absorbers, etc. In addition, spring machinery also plays an indispensable role in the electronics industry and aerospace industry.

3. Technical development of spring machinery

With the continuous advancement of science and technology, spring machinery is also constantly developing. On the one hand, spring machinery is developing towards high precision and high efficiency. By using advanced CNC technology and servo systems, spring machinery can achieve more precise processing and higher production efficiency. On the other hand, spring machinery is also gradually realizing intelligence and automation to reduce manual intervention and improve production stability and reliability.

4. Future trends of spring machinery

In the future, spring machinery will continue to develop in the direction of high precision, high efficiency, intelligence and automation. At the same time, with the continuous emergence of new materials and new processes, spring machinery will also face more challenges and opportunities. For example, with the popularity of new lightweight materials, spring machinery needs to adapt to the characteristics of these materials to achieve lighter, stronger, and more durable spring manufacturing. In addition, with the continuous development of artificial intelligence and big data technology, spring machinery is expected to achieve smarter production scheduling and optimization, further improving production efficiency and product quality.

5. Conclusion

As a key equipment for manufacturing high-precision springs, spring machinery plays an irreplaceable role in the industrial field. By having an in-depth understanding of the working principles, application fields, technological development and future trends of spring machinery, we can better grasp the development trends in this field and provide strong support for the development of related industries. At the same time, we should also pay attention to the challenges and opportunities faced by spring machinery, continue to innovate and progress, and promote the spring machinery industry to a higher level of development.

In short, spring machinery plays an important role in the industrial field, and its development history and future trends are worthy of our in-depth study and discussion. With the continuous advancement of science and technology and the changing market, the spring machinery industry will face more development opportunities and challenges. We look forward to seeing more innovations and breakthroughs in this field, injecting new vitality into the development of the industrial field.