Wire bending machine is an important metal processing equipment and is widely used in many industries such as automobile manufacturing, construction, household products, and electric power. With the continuous advancement of science and technology and the increasing expansion of the market, the functions and performance of wire bending machines are also constantly improving, becoming an indispensable and important tool for modern metal manufacturing.

The main working principle of the wire bending machine is to bend the wire through the bending mechanism to achieve the required shape and angle. Its structure generally consists of a fuselage, workbench, bending mechanism, transmission mechanism, control system and other parts. The fuselage is the main part of the equipment, the workbench is used to place the wire to be processed, and the bending mechanism is driven by the transmission mechanism to complete the bending action of the wire. The control system is responsible for controlling the operation of the entire equipment, including setting parameters such as bending angle and speed.

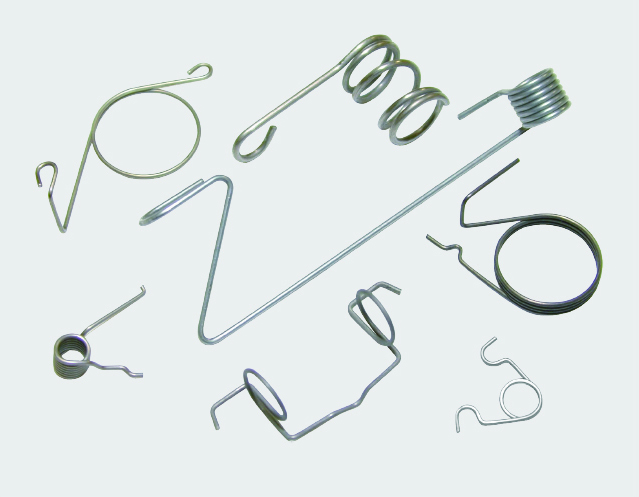

Wire bending machines are widely used and can be used to process various types of wires, such as steel wire, iron wire, copper wire, aluminum wire, etc. In the automobile manufacturing industry, wire bending machines are widely used in the production of automobile seat frames, door lock levers, snake springs and other components. In the construction industry, wire bending machines can be used to process various doors, windows, railings, brackets and other metal products. In addition, wire bending machines also play an important role in household products, electric power, electronics and other industries.

When choosing a wire bending machine, you need to make a selection based on actual production needs and processing requirements. Generally speaking, factors such as the accuracy, tonnage, structure, brand and service of the equipment need to be considered. Accuracy is one of the important parameters of the wire bending machine, which determines the quality and accuracy of the processed wire. The tonnage determines the wire diameter range that the equipment can process. In terms of structure, it is necessary to select a suitable equipment structure according to actual production needs, such as the structure of replaceable molds, etc. Brand and service are also factors that need to be considered when choosing a wire bending machine. Well-known brands and equipment with complete after-sales service can ensure the stability and reliability of the equipment.

When using a wire bending machine, you need to pay attention to the maintenance and upkeep of the equipment. Cleaning the equipment regularly and keeping the equipment clean and hygienic can effectively extend the service life of the equipment. At the same time, lubrication and maintenance of equipment can reduce equipment wear and failure rates. In addition, various components of the equipment, such as bending mechanisms, transmission mechanisms, control systems, etc., need to be checked regularly to ensure their normal operation.

In short, the wire bending machine is an indispensable and important equipment in the metal manufacturing industry. Its wide range of applications and continuously improving performance provide strong support for the development of various industries. When selecting and using a wire bending machine, it needs to be selected and maintained according to actual production needs and processing requirements to ensure the stability and reliability of the equipment and provide a solid guarantee for the production and development of the enterprise.